Closed Liquid Diode Medical Catheters via Microfluidics | Final Research Outcomes

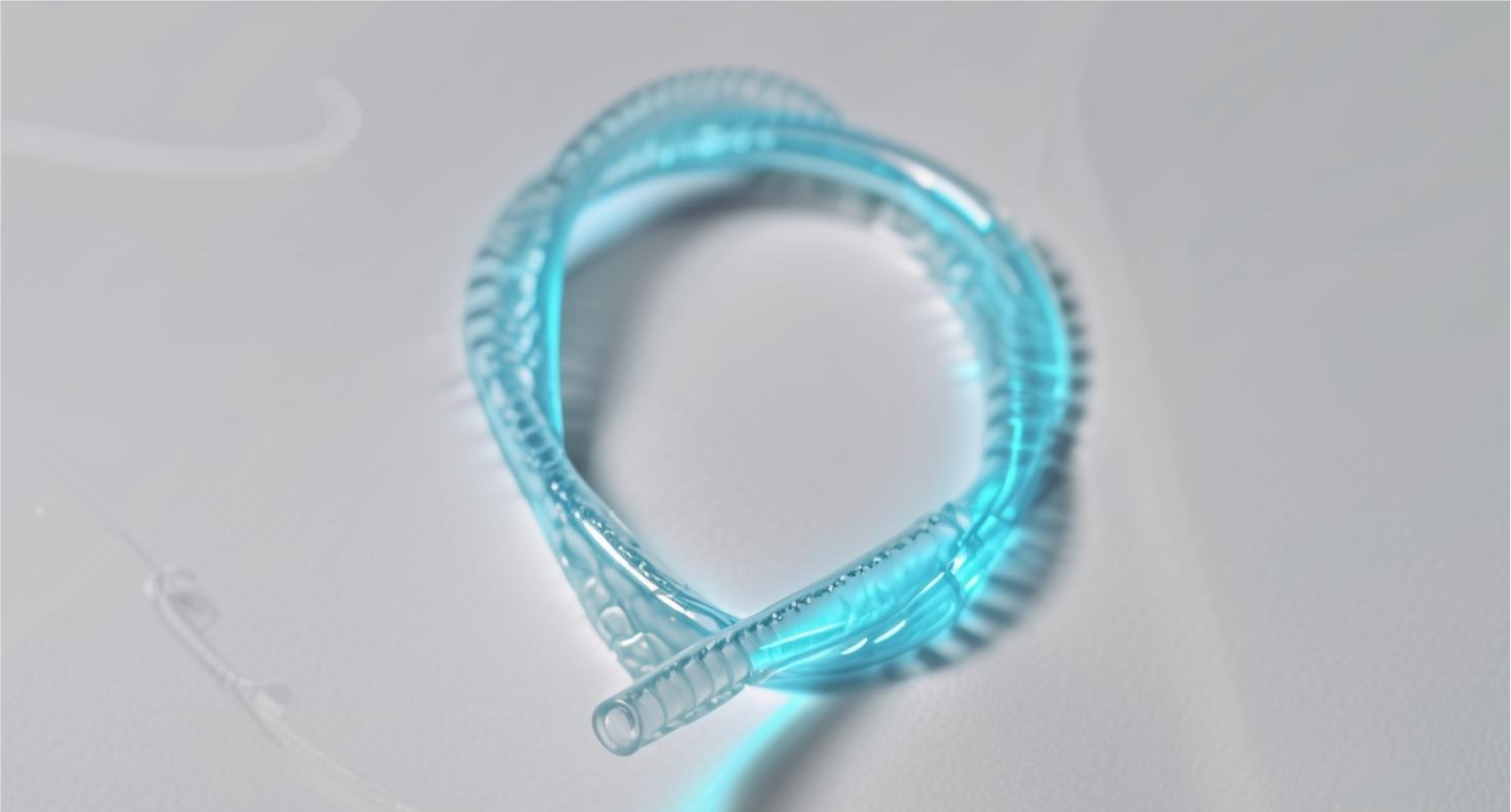

Prototype and core microstructure of the microfluidic closed liquid diode medical catheter

Prototype and core microstructure of the microfluidic closed liquid diode medical catheter1. Project Overview

This project has successfully developed and validated microfluidic-based closed liquid diode medical catheters to address critical limitations of conventional PVC/TPE medical catheters (reflux, bubble entrapment, high flow resistance). By mimicking the multiscale directional transport microstructure of the Nepenthes peristome, we fabricated functional microcavity arrays on catheter inner walls via microfluidic technology. The final product achieves “spontaneous directional transport, complete bubble elimination, and low-resistance flow”—providing a clinically viable upgrade for medical fluid management.

2. Core Technical Breakthroughs

2.1 Scalable Microfluidic Fabrication Process

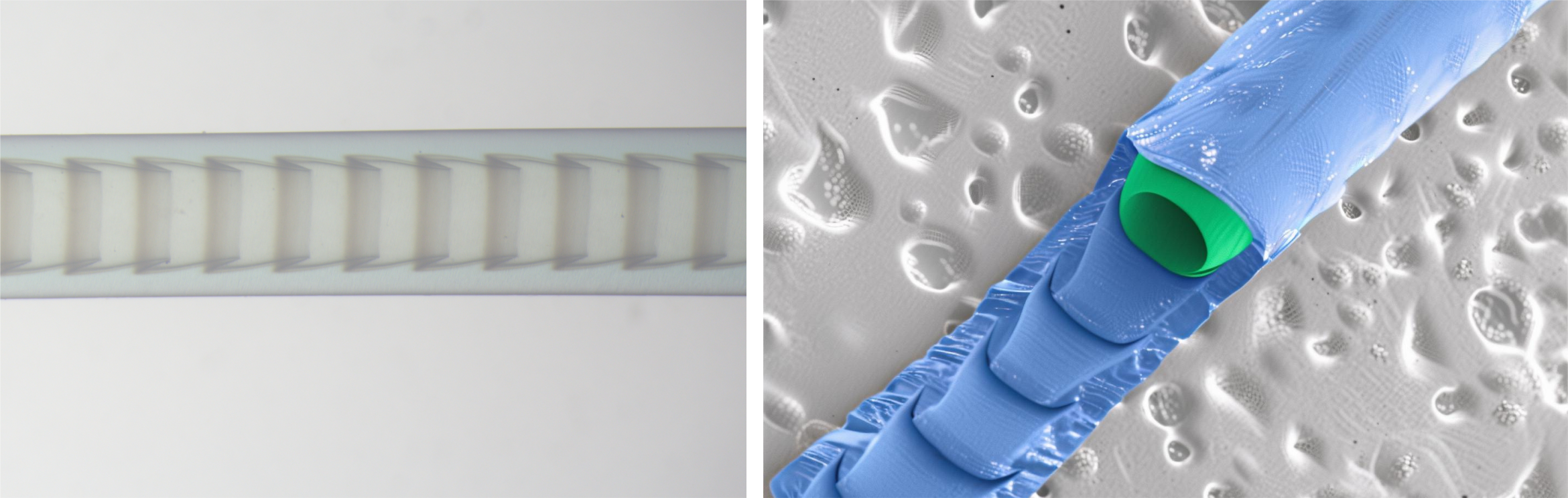

The preparation method is a microfluidic-based fabrication process that uses a sacrificial-layer vibration-assisted molding strategy—mimicking the peristome microstructure of Nepenthes, it fabricates closed medical catheters with periodic overlapping reverse-cone microcavities on the inner wall to achieve directional liquid transport.

A sacrificial-layer vibration-assisted molding process was developed for mass production Photograph of a liquid diode microtube Photograph of a liquid diode microtube

SEM images showing the microstructure of the microtube

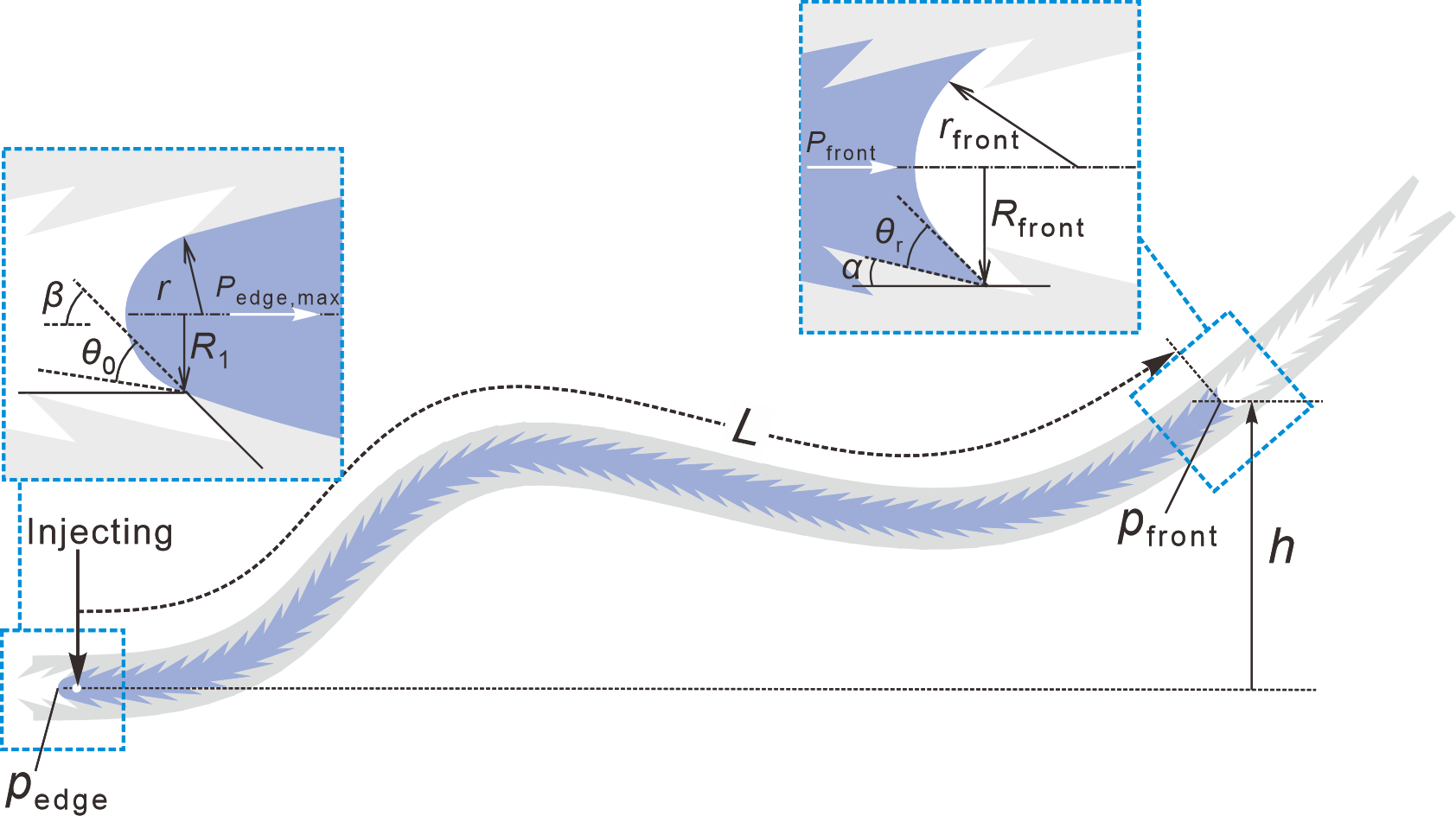

Schematic of continuous liquid injection, incorporating microstructures, liquid properties, injection flow rate, and plug length, with consideration of gravity

Significance Statement

Directional liquid transport within confined spaces is crucial for both fundamental studies and industrial applications. Despite extensive progress in engineering diverse open surfaces to rectify liquid transport, the implementation of diode-like liquid transport in closed spaces is still challenging. In this study, we present introduces a flexible liquid-diode microtube designed specifically for directional liquid transport in confined spaces, achieved through multimodal microfluidics. Besides, a flow lithography modality is introduced to produce short microtube segments to construct a fluidic-electronic circuit with the ability to execute dual logic control.